Intuitive design for easy operation

With its customizable feature, you can directly select your source processes by adding 99 programs to your favorite processes. The easy-to-read, intuitive user interface saves you time.

High frequency ignition

HF high frequency ignition overcomes the air gap between the electrode and the workpiece and prevents direct contact, thus avoiding the formation of tungsten residues after welding.

Lift Tig

Without high frequency and high voltage, it enables arc initiation without adhesion by touching the electrode to the workpiece.

2T/4T

Manual and automatic triggering improves the welder’s control capability and working ergonomics.

Aesthetic spot welds

The spot function is the application of a predetermined current intensity and duration to the weld metal at a fixed electrode distance, especially with the touch and breakaway motion. In this way, the current intensity, duration and arc height are adjusted by the machine to achieve 100% repeatable spot welding results.

sPulse

Timed pulse currentsPulse provides precise handling, low heat input, high melting strength and quality weld seams thanks to the independent adjustment of the duration of the pulse top current and bottom current.

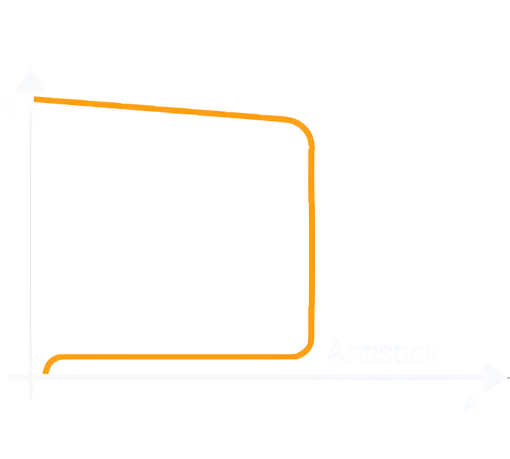

FPulse

Frequency-dependent pulse currentFPulse provides easy use, low heat input, high melting power, and quality weld seams thanks to the ability to adjust the pulse peak current and base current in a frequency-dependent 50/50 ratio.

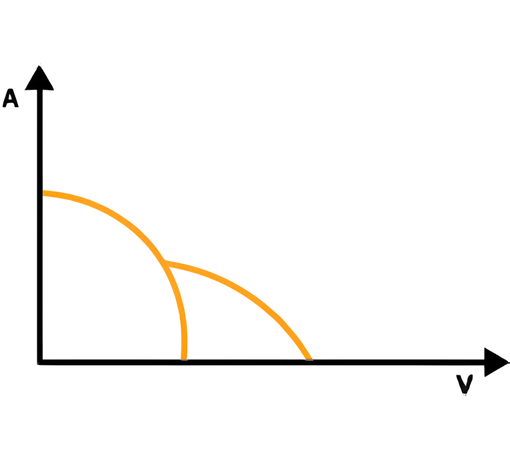

APulse

Automatic, synergic, pulseAPulse provides fast handling, low heat input, high melting power and quality weld seams thanks to synergic adjustment of the pulse frequency depending on the main current.

Highly efficient root source

CEL enables continuous arc welding on cellulosic electrodes, resulting in weld seams with a flawless appearance. It offers adapted welding characteristics for more efficient use in position welding.

Hot Start

It facilitates the holding of the coated electrode at the beginning of welding, preventing it from sticking.

Consistent welding penetration and secure root joint

It enables the electrode to melt without sticking at low current levels according to the electrode diameter. It facilitates welding by reducing heat input in position welding.

Smart power supply

If the electrode sticks to the workpiece, it provides easy separation and prevents damage to the electrode.

Reach Us

LET’S CREATE SOLUTIONS FOR YOU.

Share your opinion and inquiry with us and we’ll get back to you as soon as possible.