MX600 Pulse

quick guide

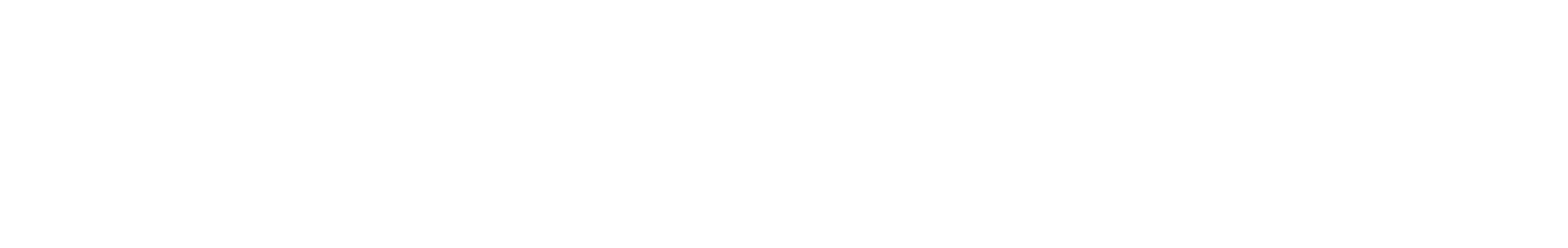

(1) Wire Feed Speed

(2) Welding Current

(3) Material Thickness Selection

(4) Above Menu Selection / Function Settings

(5) Trigger Selection

(6) Material Type Selection / Press and Hold for Manual Welding

(7) Wire Diameter Selection / Press and Hold for TIG Welding

(8) Shielding Gas Selection / Press and Hold for MMA Welding

(9) Standard Process Selection

(10) X Process Selection

(11) Above Menu Selection / Job Settings

(12) Inductance

(13) Voltage

(14) Program Memory

(15) Hold Indicator

(16) Lock Indicator

(17) Trigger Indicator

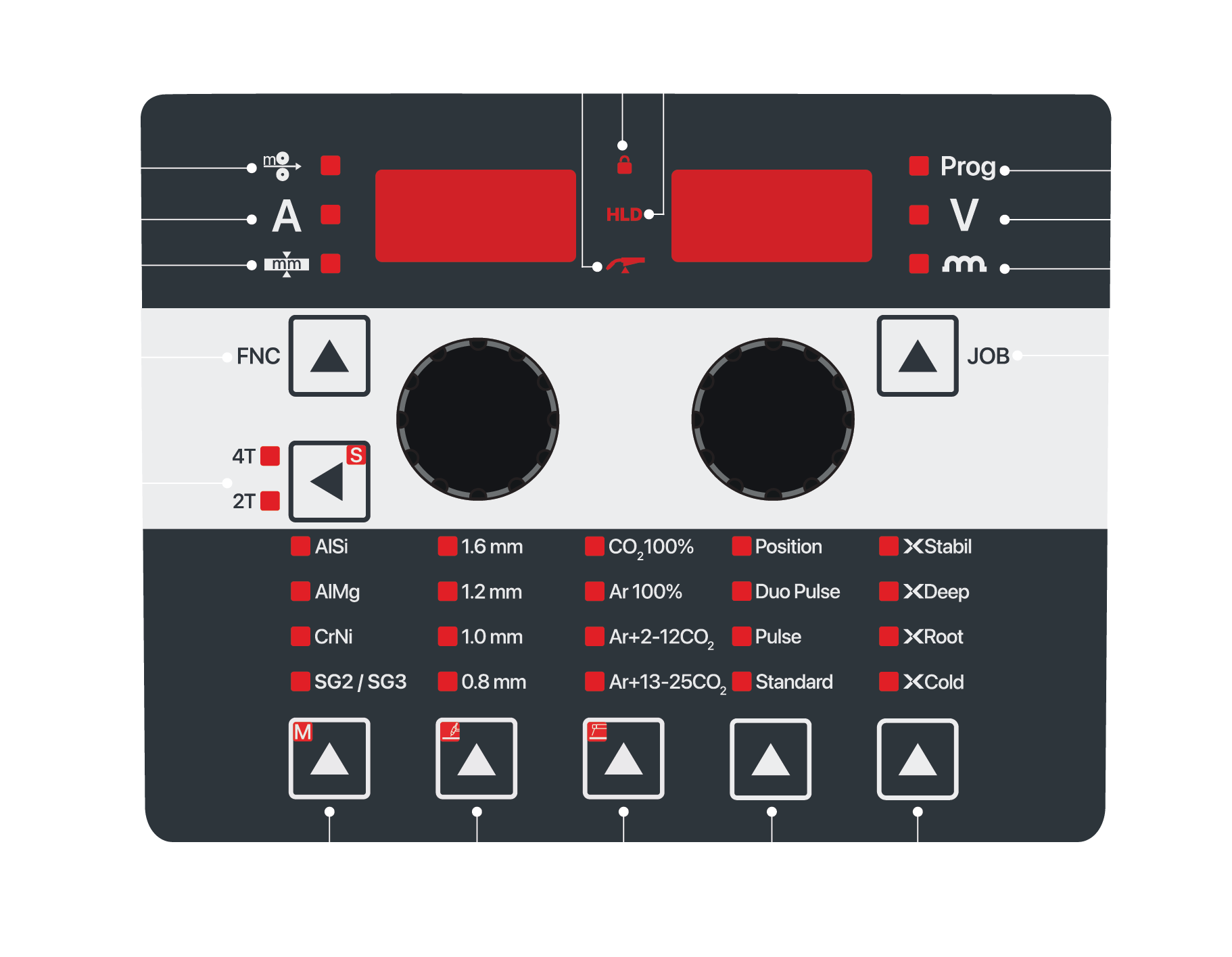

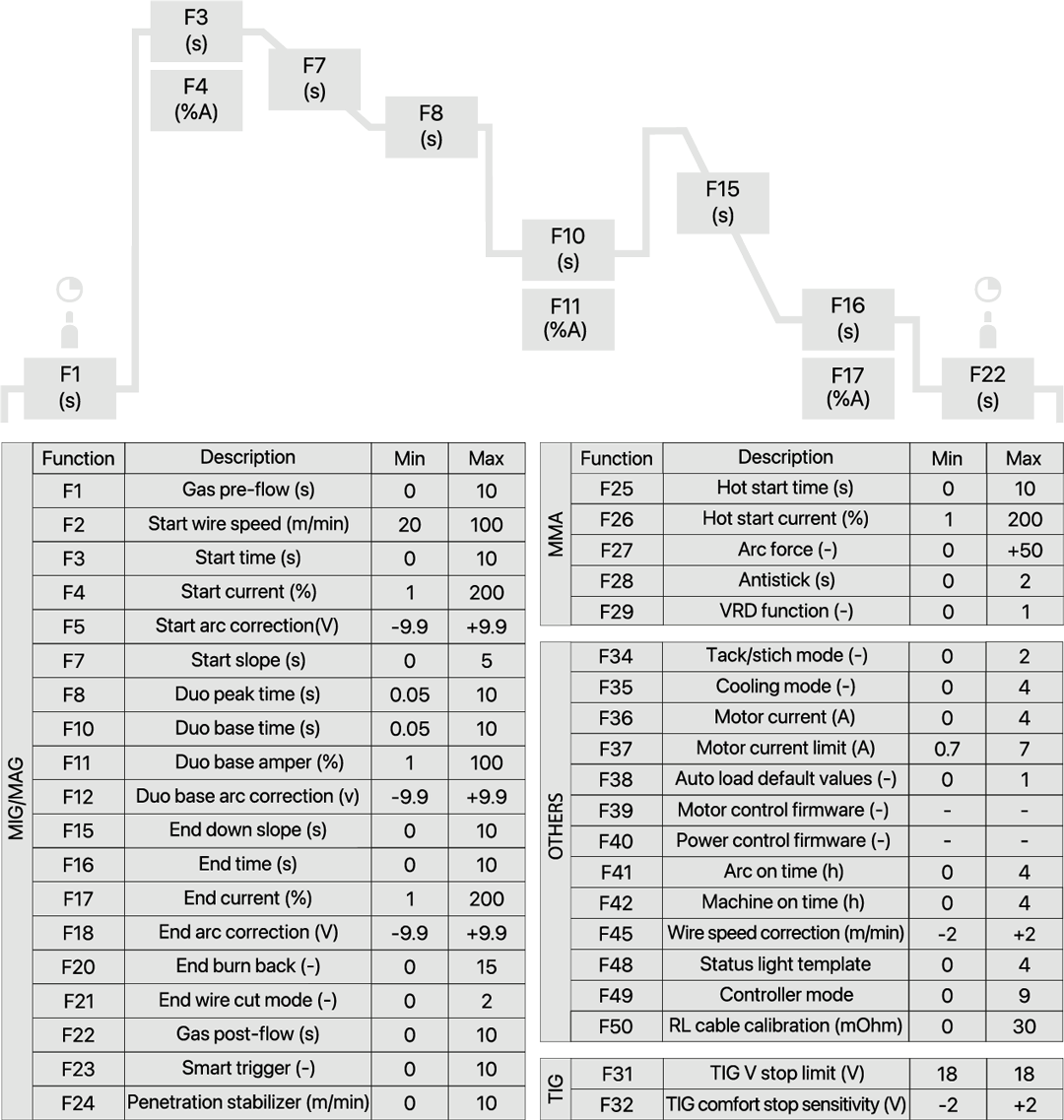

MIG / MAG Functions

F1 Gas Pre-Flow

Allows to regulate the duration of the shielding gas flowing before arc ignition to form

the protection gas cloud around ignition area. Usual set rule of thumbs: 0.1*Torch hosepacklength.

Unit: s

Setting range: 0 – 10

Factory setting: 0.1

F2 Wire start creep speed

Defines how fast the wire approach the workpiece before arc ignition related to main wire.

Lower values lead to softer ignition, higher values provide immediate start with minimal delay,

but the probability of ignition spatters occurs. The creep speed is limited in the range 1.5…11 m/min.

Unit: %

Setting range: 20 – 100

Factory setting: 1

F2 Wire start creep speed

Defines how fast the wire approach the workpiece before arc ignition related to main wire.

Lower values lead to softer ignition, higher values provide immediate start with minimal delay,

but the probability of ignition spatters occurs. The creep speed is limited in the range 1.5…11 m/min.

Unit: %

Setting range: 20 – 100

Factory setting: 1

About us

Providing the Highest Quality Carpentry Services In the Area

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Maecenas faucibus mollis interdum. Vestibulum id ligula porta felis euismod semper. Fusce dapibus tellus ac cursus commodo, tortor mauris condimentum nibhLorem ipsum dolor sit amet, consectetur adipiscing elit. Maecenas faucibus mollis interdum.

Vestibulum id ligula porta felis euismod semper. Fusce dapibus tellus ac cursus commodo, tortor mauris condimentum nibhLorem ipsum dolor sit amet, consectetur adipiscing elit. Maecenas faucibus mollis interdum. Vestibulum id ligula porta felis.