MX350

RoboticSpatter-free steel welding

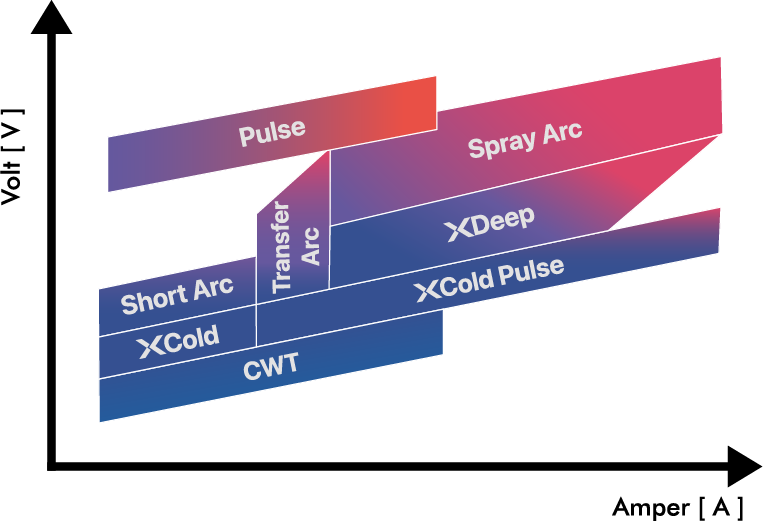

Pulse technology ensures high quality welding results without the need for a difficult to control transition arc that can cause spatter. Smart welding solutions eliminate post-weld cleaning and spatter at the same time.

Intuitive design for easy operation

MX350C Pulse offers an intuitive interface that highlights the settings users use most frequently. In addition, Joband function tables with hundreds of options are available in the background to provide detailed operating options.

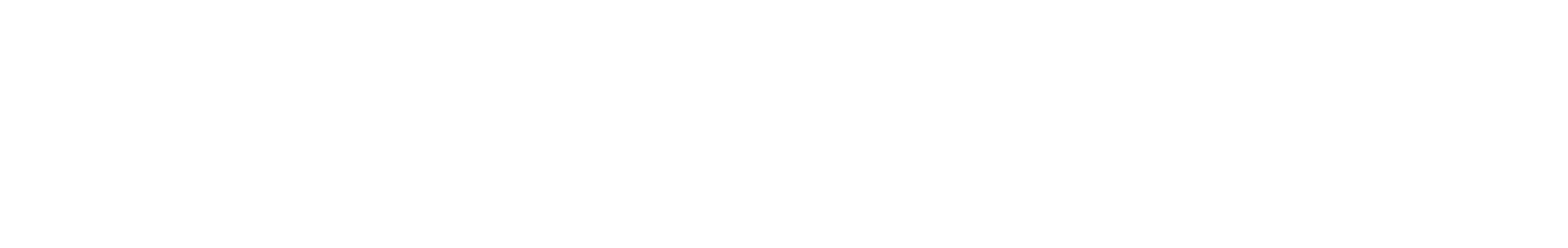

Experience 406 welding program

MX350C Pulse has 406 welding programs that facilitate the welding of steel, stainless steel, aluminum, copper, andzinc alloys, eliminating spatter and the need for post-weld grinding, and it has a memory capacity of 99 programs.

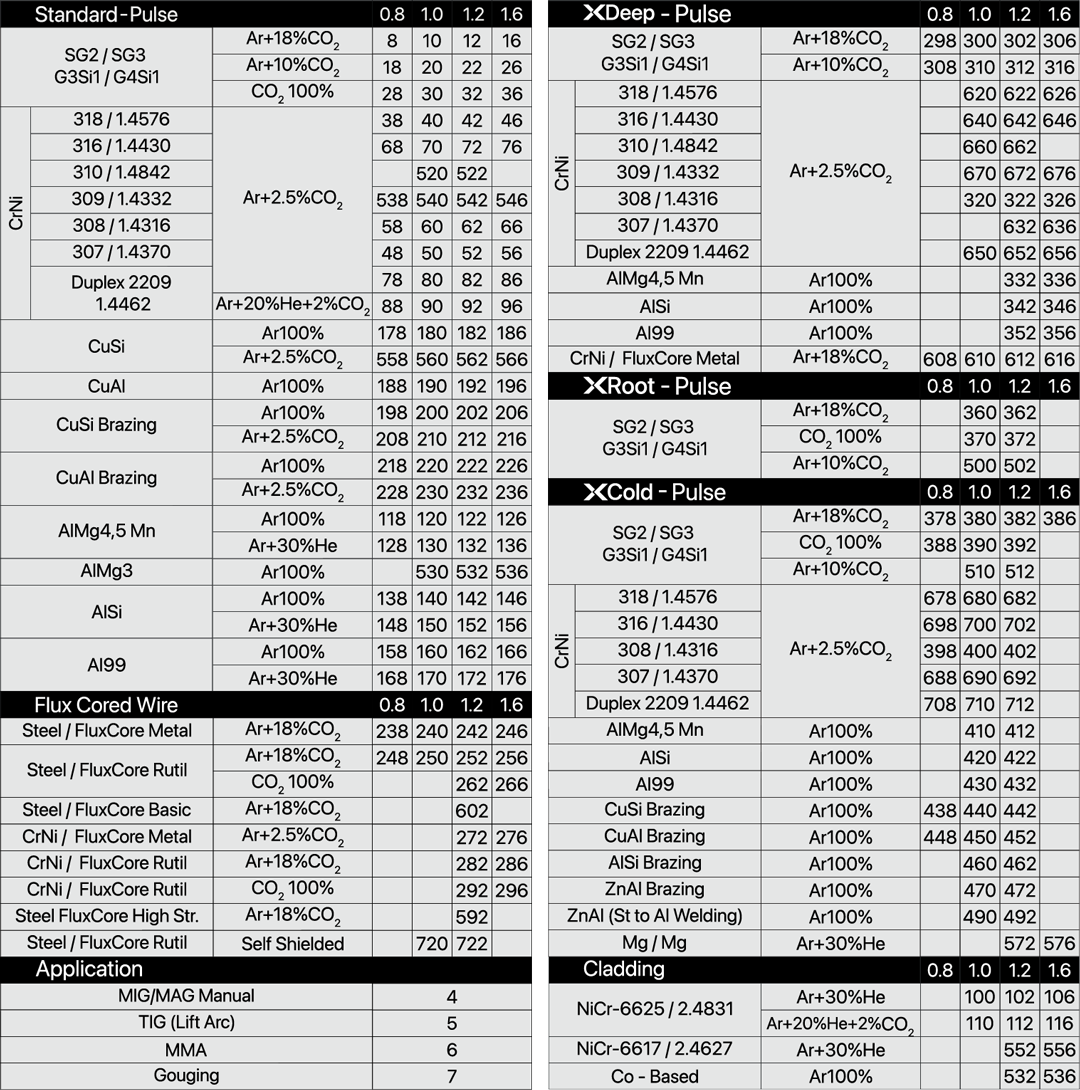

Advanced function table

Function table for MIG/MAG, TIG and MMA welding, allowing advanced settings to be adjusted as needed.Maximizes the welding experience.

High welding speed, low heat input

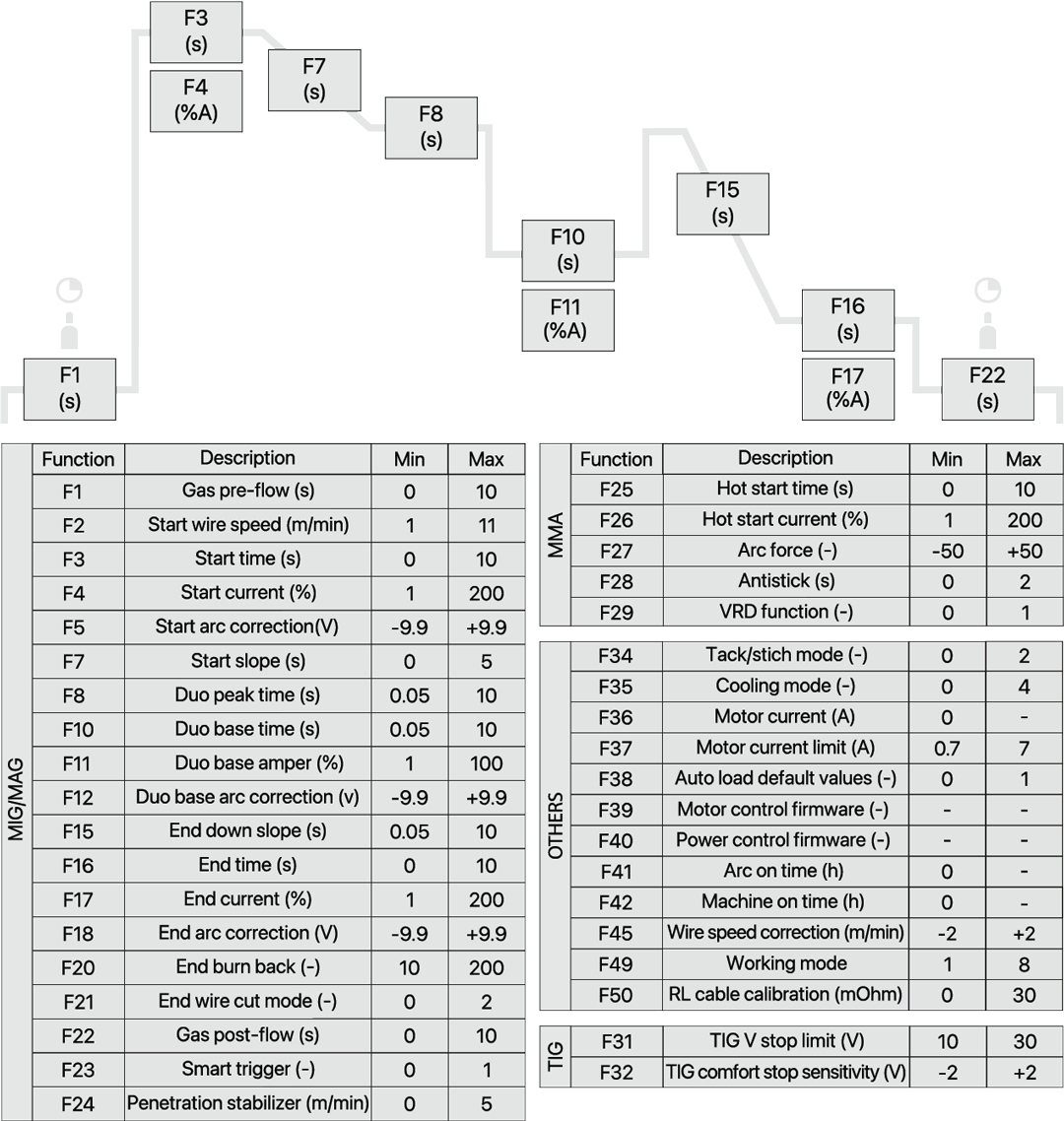

Synergic keeps the voltage constant after droplet transfer by rapidly reducing the welding current vertically to acertain reference level. This increases the welding speed, resulting in low heat input and an intensified arc.

No spatter welding technique

Pulse eliminates post-weld cleaning and spatter in the welding of aluminum, stainless steel and all metal alloys, providing flawless welding performance.

Flawless welding of thin materials

Duo Pulse effectively performs in high and low welding power cycles, providing penetration at high power and cooling the weld pool at low power. These features enable achieving flawless results in thin materials, corner welds, and high precision applications.

Easy control in vertical and overhead welding positions

Position works effectively in both high and low welding power cycles, providing penetration at high power and cooling the weld pool at low power. These features enhance control and confidence when working in vertical and overhead welding positions.

Eliminate high heat input

XCold, performing short circuits at a low current level, enables high melting power and quality weld seams with low heat input.

Highly efficient root source

XRoot, performing short circuits at a low current level, provides excellent root penetration with high arc pressure for gap bridging in all positions.

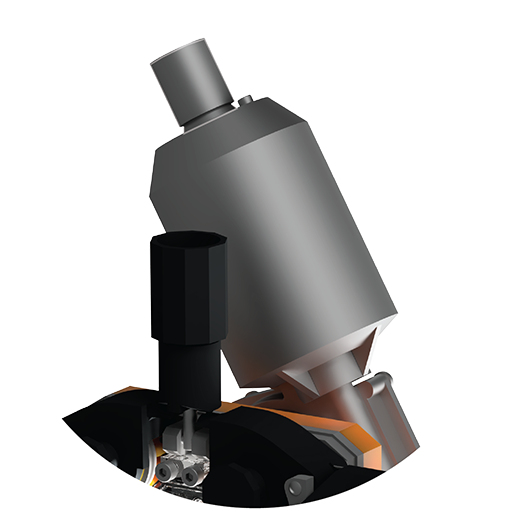

High welding efficiency in thick metals

XDeep operates in the spray arc area. With high-frequency and low amplitude current pulses, it provides high feed rate and low heat input, especially in steel and stainless steel welding applications in the PA and PB positions. This effectively reduces labor time and welding costs.

100% Penetration

If the free wire length is high (the contact nozzle is too far from the workpiece), the reference current drops and the penetration decreases in order to keep the voltage constant. If the reference current is lower than expected, XStabil increases the wire speed to prevent the reference current from dropping and keep the penetration constant.

%

Switch-on, 40°C

Welding program

%

Reduced re-processing

%

Faster welding

Remote controlled torch

The ability to adjust wire speed, arc height, and program memory before or during welding without accessing the machine’s user interface enhances the comfort and productivity of the welder.

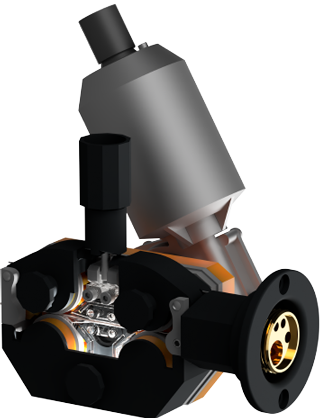

4x4 wire feeder unit

With 4 channels and 4-groove, 32 mm ball-bearing wire feed rollers, a strong grip is provided to the wire without damaging its physical form. This feature enables uninterrupted wire feeding while eliminating wire breakage issues.

256 PPR optical counter

By controlling the wire speed 50.000 times per second, it ensures that the welding wire reaches the weld pool at a constant rate. This feature minimizes the impact of conditions that negatively affect wire feeding speed on the weld, such as torch bending, contamination in the wire path, and narrowing of the contact tip diameter.

Hose pack support

The easily removable hose support ensures that the power cable, communication cable, gas and water hose components are securely attached to the machine. It also prevents damage to the hose package by preventing the outer cover from peeling off during movement.

Wire forward, wire retract, and gas test

Allows wire and gas adjustments to be made quickly, easily and safely before welding. Prevents gas waste.

Smart cooling

Intelligent cooling fan technology, which is only activated when needed, reduces noise, dust accumulation inside the machine and energy consumption. Increases cooling fan and fluid pump life up to 7 times.

Military standard connector

It offers durability, sealing, protection against electromagnetic interference, high transmission performance and easy removal and installation.

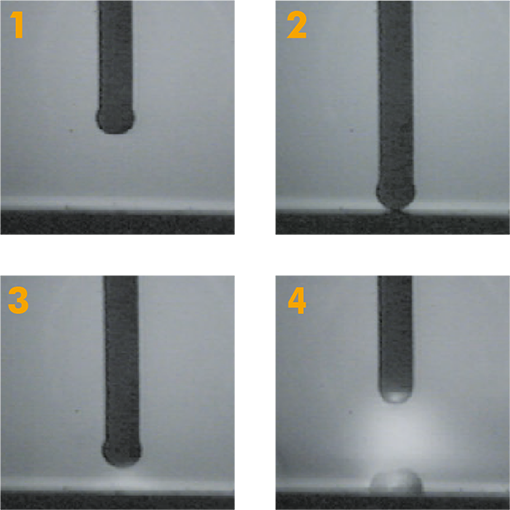

Touch arc ignition

Unique arc starting parameters are applied for each job. The wire makes contact with the workpiece at a lower speed. When is initiated, speed automatically increases. This technology reduces tip wear, increases productivity, and prevents errors in welding arc.

Adaptive arc control

A dual-core microprocessor with arc control 40,000 times per second regulates the reference current to maintain a constant height. This technology improves weld bath and increases productivity.

Advanced welding processes

Maximum welding performance with optimized heat input, minimum deformation, high deposition rates and speed for aluminum, carbon stainless steels, other metal alloys are provided.

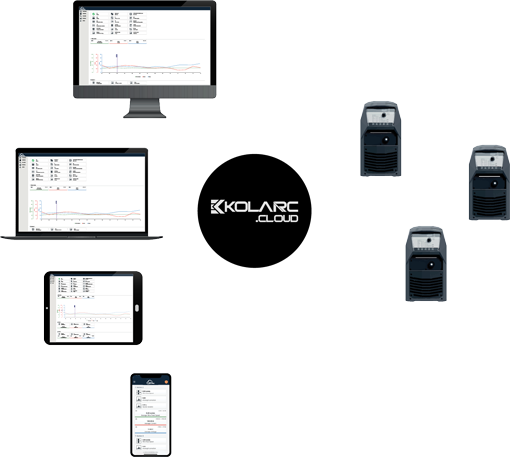

Efficiency, cost optimization, maintenance and quality management are secured with Kolarc.Cloud!

View

Reach Us

LET’S CREATE SOLUTIONS FOR YOU.

Share your opinion and inquiry with us and we’ll get back to you as soon as possible.